Industry 4.0 development requires an integral view of flexible production systems. The design of uniform mechanical interfaces is just as necessary as the definition of uniform interfaces for the collection and processing of data in the course of digitization.

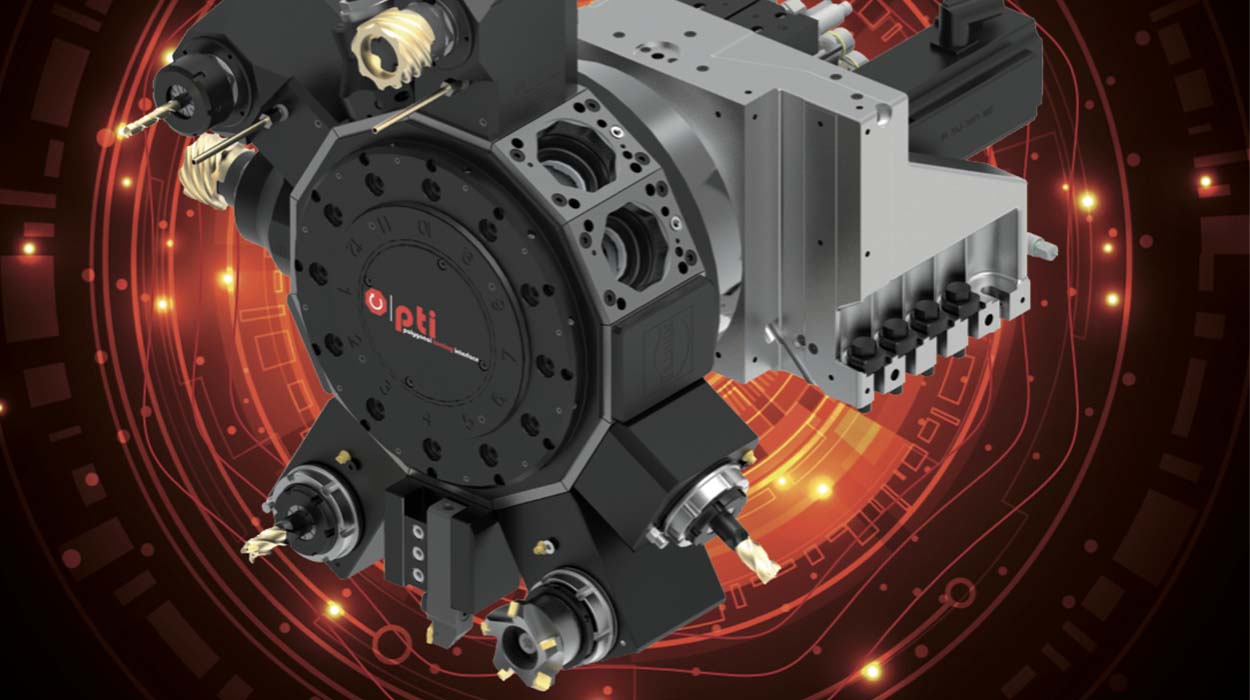

8-fold polygonal tool interface

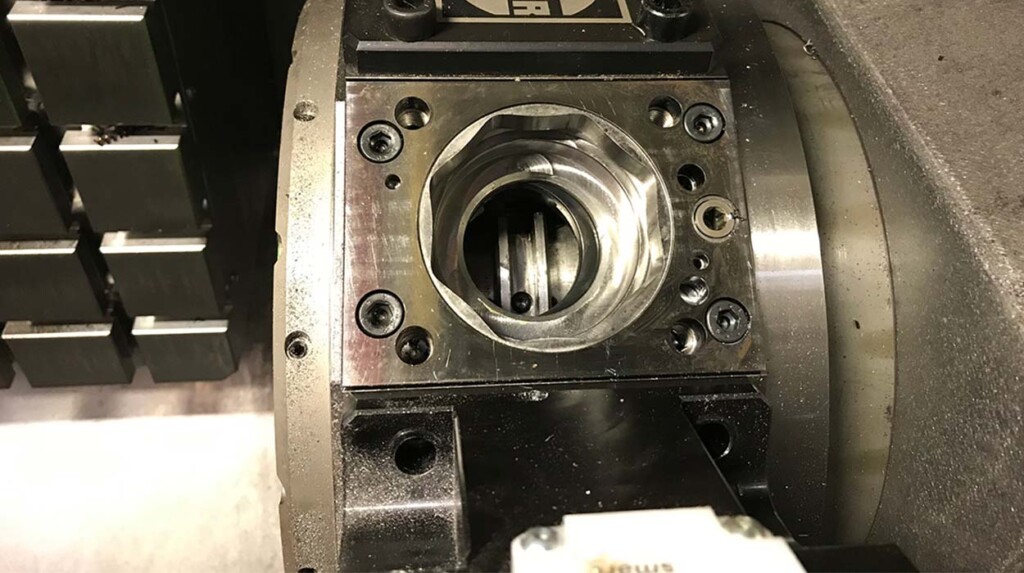

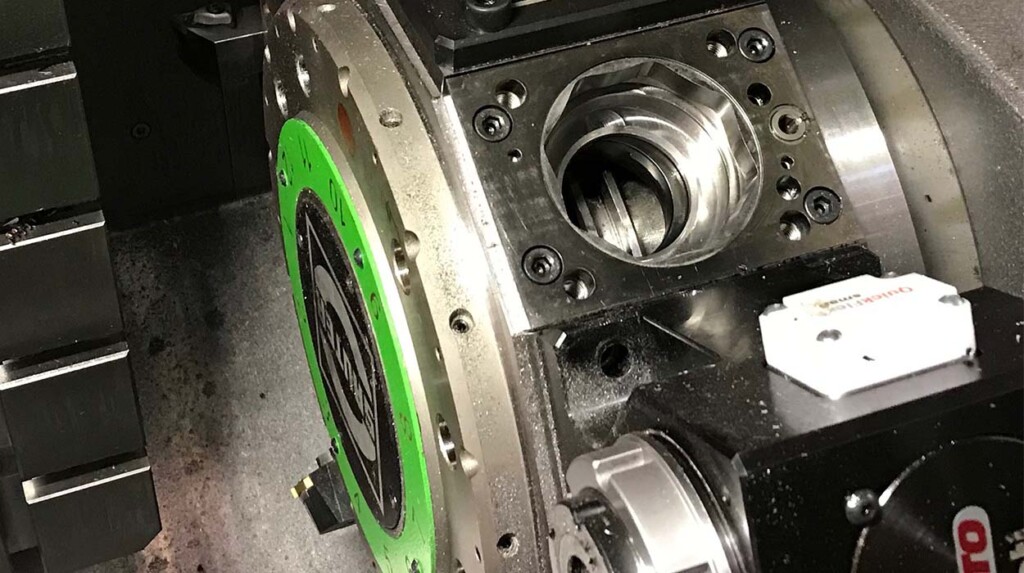

Uniformity, performance and flexibility are the hallmarks of the new turret interface PTI (polygonal turning interface). As a uniform mechanical interface, this interface creates the conditions for the flexible equipment of modern lathes with precise, high-performance toolholders and driven tools. The media supply (coolant, air) and the data and energy transfer complete the PTI interface.

With the developed interface the mechanics and media supply and provide space for elements of data and energy transfer. Due to its outstanding performance the new, future-oriented interface is suitable for both in series production and for flexible parts production and is introduced in various areas of industry.

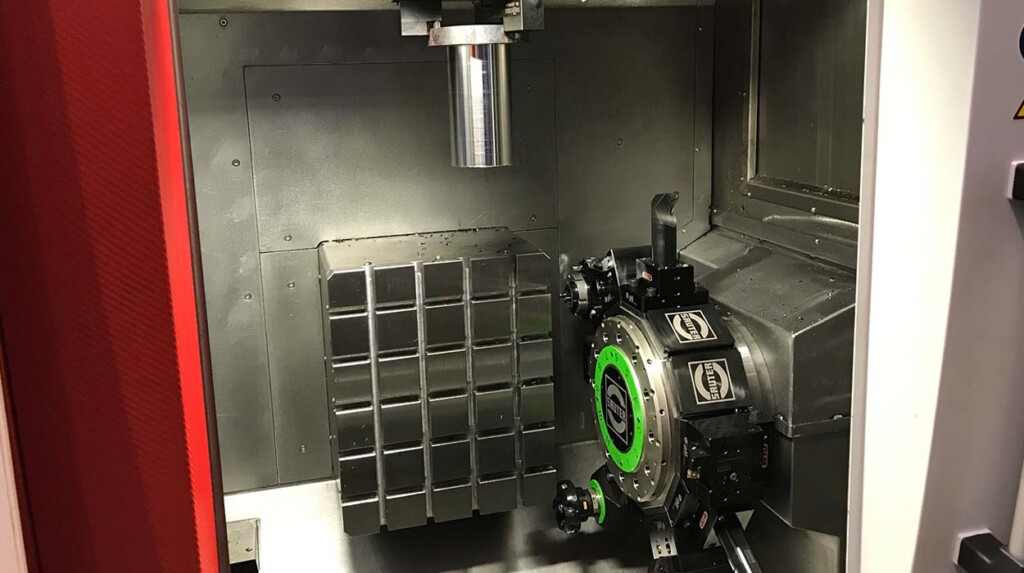

In the funding project REKUNORM the last gap is closed at the design of the new turret interface. Weisser completes the team of the pti-working-group and is the first manufacturer to integrate a turret in a turning centre. With a power of up to 80 kW and a torque of 1,250 Nm the machine is a basis for a solid realization of the performance of the PTI65 interface.

As a pioneer of out-of-round turning technology, Weisser is a manufacturer of PTI parts. Tool blanks with PTI shank as well as PTI receivers are produced on Weisser out-of-round turning centers.

Features

- Positive locking (polygon) torsional rigid

- Large shaft diameter DTH powerful coupling

- Data and power transmission equipped for i4.0

- Automatic clamping possible suitable for lightly-manned operation

- Face contact and clamping system bending rigid

- Supply of coolant and sealing air technologically comprehensive

- Small dimensions compact

- Consideration of tool adapters universal

- Tapered polygon shank repeatable

- Tool holders are 180° convertible function expanding

- Manual quick change cost-saving

- Intended for standardization uniform

Further Information: