At the beginning of its activities as a machine manufacturer, the company initially developed and built lathes for the Black Forest watchmaking industry. The product range then expanded to include lead and pull spindle lathes, milling machines, jointers and also grinding machines. In the early 1950s, the company focused on automatic lathes. Today, multifunctional turning centers are manufactured. WEISSER passes on this know-how, gained in over 160 years of experience, to its customers with the aim of finding the best possible solution.

History

1830

Johann Georg Weisser manufactures small lathes and vices in his “Schlosser und Zeugschmiede” (locksmith’s and toolsmith’s shop) already with two journeymen.

1842

The relocation of the new post road, which now no longer runs through Langenschiltach, makes it necessary for Weisser to move. He leaves Langenschiltach and sets up a blacksmith’s shop in St. Georgen, four kilometers away on the newly built post road.

1856

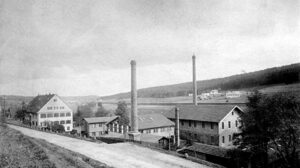

With the foundation of the machine factory J.G. WEISSER Söhne in 1856, factory production of machines and tools begins. The shoeing of post and freight horses is no longer carried out at the new location. However, the name “Postschmiede” has remained with the WEISSER company until today, especially in the linguistic usage of the employees and inhabitants of St. Georgen.

1911

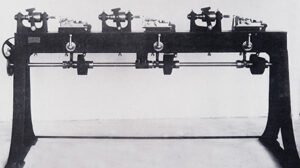

Already at this time the first automatic lathes are built, for example a single spindle automatic for the production of barrel turned parts and screws, the ZH/ZC with drum cams for material feed and longitudinal slide, as well as disc cams for two facing slides. In addition, an automatic drilling and facing machine with three workstations, with shaft drive and coupling for each station.

1954

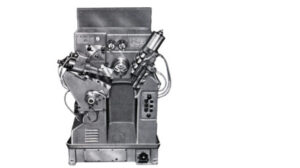

The legendary era of the FRONTOR series begins. The FRONTOR has a short machine bed, since at that time 80% of all turned parts are shorter than their diameter. The first face-operated chuck-type automatic lathe becomes a decisive trend in lathe construction.

1981

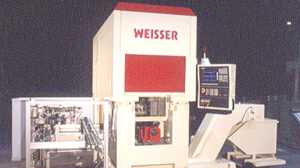

Development of the DZ turning spindle machine with a pivoting, tapered spindle carrier. While the horizontal turning spindle is machining the workpiece, the vertical turning spindle is loading and unloading. Swiveling the turning spindle into the work area significantly reduces non-productive time. Difficult-to-clamp and large workpieces are the field of application of the DZ 300.

1990

Construction of the first PICK-UP lathe according to WEISSER patent of 1987. In this year the previous lathe design is completely redefined. A movable PICK-UP motor spindle picks up the workpiece from a conveyor belt for machining and returns the finished part there. With easy loading and unloading, which previously required complex and expensive gantries, PICK-UP machines are more compact and less expensive.

2016

160 years of J.G. WEISSER SÖHNE – the anniversary is celebrated with a big ceremony.

2021

Hardinge acquires J.G. WEISSER GmbH and integrates it into its portfolio. The business areas remain unchanged, as does the St. Georgen site. The acquisition by the Hardige Group results in additional synergies for J.G. WEISSER in the market.

Today

WEISSER is characterized by numerous technical innovations and high solution competence. The history of WEISSER makes it clear that many ideas, progressive thinking and consistent customer orientation have always successfully influenced the development of the company since its foundation.