UNIVERTOR AS Series

Available in two machine sizes

Left and right machine variants available

High dynamics of all axes

IN THE VERSION WITH PICK-UP LOADING

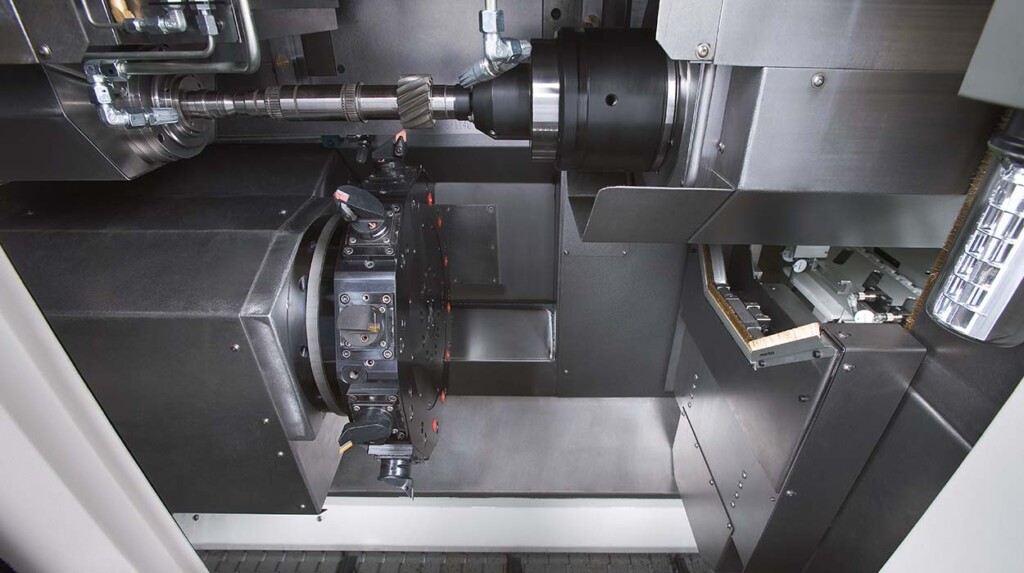

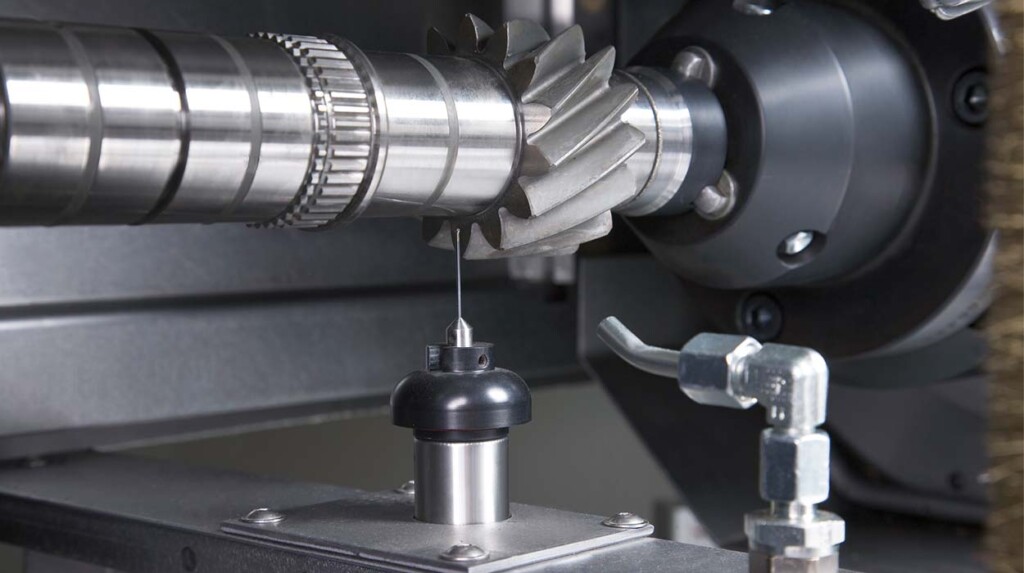

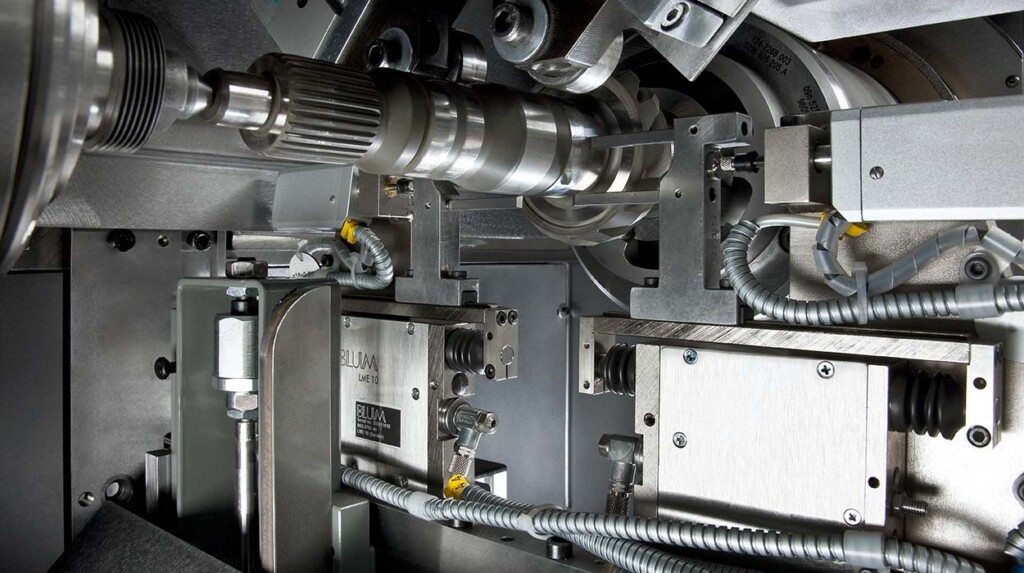

Modular designed, single-spindle pick-up precision turning machine. Designed for complete machining of various batch sizes at low unit costs and with high machining and quality requirements. Due to the automation solution integrated as a pick-up system, no loading devices or separate robot solutions are required. The cross slide of the UNIVERTOR AS, that carries both the motor spindle and the NC tailstock, is designed horizontally. The tailstock and steady rests travel NC-controlled.

CONCEPTUAL ADVANTAGES PICK-UP LOADING

- Available in two machine sizes

- Machine columns with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides with high accuracy and preload classes in all axes

- Direct path measuring systems in all axes (glass scales)

- High dynamics of all axes

- In-house built turning spindles with very good accuracy values within concentricity and axial run-out

- Simple installation and disassembly of the turning spindle in case of repair needs

- Green turning, hard turning, scrubbing, and finishing operations

- Simple automation, only conveyor belt required

- Patented pick-up principle optimized for machining of shaft parts

- Proven machine concept with over 500 machines built

- Compact footprint

- Main spindle A6 according to DIN 55026

- Tailstock with MK 4 mounting

- Tool turret interface VDI or Capto possible 4

OPTIONS PICK-UP LOADING

- Driven tools possible (for drilling operations)

- Rotational turning possible

- NC adjustable steady rest possible

- Integrated measuring probe possible

- Additional external grinding unit possible

- Loading via NC shuttle possible

Technical data pick-up

AS90/400 (Pick-Up)

AS90/650 (Pick-Up)

Max. turning diameter

160 mm

160 mm

Max. chuck diameter

215 mm

215 mm

Max. peak distance

max. 740 mm

max. 990 mm

Max. Feed force X/Z (40 % CDF)

10 / 8 kN

10 / 8 kN

Working stroke X/Z-axis

280 / 1.130 mm

280 / 2.400 mm

Max. Process speed X/Z

30 / 60 m/min

30 / 100 m/min

Ball screw diameter X1/Z1

40 / 40 mm

40 / Linear motor mm

Number of tools

12 ( 2x)

12 ( 2x)

Tool holder

VDI 40

VDI 40

Tool flight circle

600 or 650 mm

600 or 650 mm

Main spindle

AS 90/400

AS90/650

Spindle bearing diameter

90 mm

90 mm

Spindle flange

A6

A6

Drive power 100/40 % CDF

18/23 or 23/30 kW

18/23 or 23/30 kW

Rated speed

1500 1/min

1500 1/min

Max. Speed

4.500 1/min

4.500 1/min

Torque 100/40% CDF

115/146 or 151/191 Nm

115/146 or 151/191 Nm

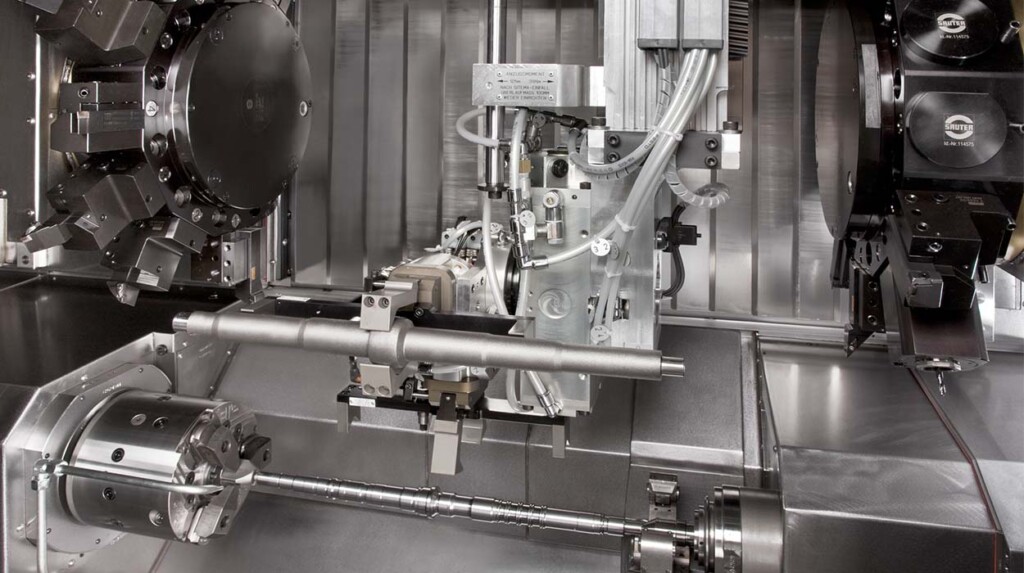

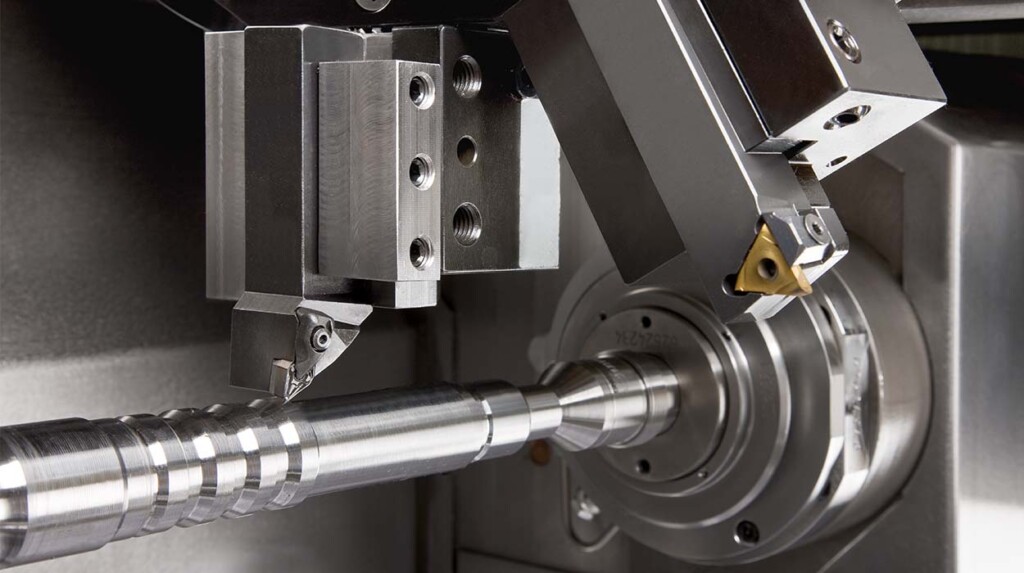

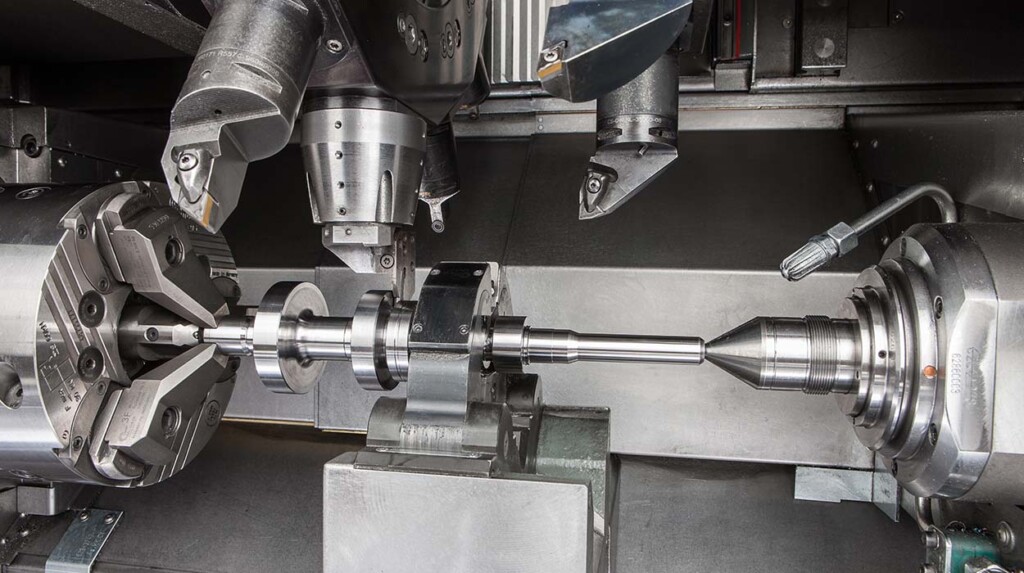

IN THE VERSION WITH PORTAL LOADING

The horizontal shaft turning machine is equipped with a main spindle with a tailstock or a counter spindle. The highly productive simultaneous machining in one machine with up to two powerful disc turrets (4 axes) enables intelligent technology processes with high savings potentials and also offers highly precise machining results. In addition to good dynamics and the high rapid traverse speeds, this series has excellent damping properties and thus first-class accuracy behavior. Workpieces can be machined up to a workpiece length of 800 mm.

CONCEPTIONAL ADVANTAGES PORTAL LOADING

- 2-axis machining or 4-axis machining possible

- Machine column with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- Direct path measuring systems in all machining axes (glass scales)

- High dynamics of all machine axes

- Self-built turning spindles with very good concentricity and axial runout accuracy values

- easy installation and removal of the turning spindle in the event of repairs

- Green turning, hard turning, rough machining, finishing possible

- Main spindle available in four power sizes (A6 or A8 according to DIN55026)

- Tailstock with MK 4 or MK 5 mounting possible

- Instead of tailstock also counter spindle in four power sizes possible (counter spindle principle)

- Interface in tool turret VDI or Capto

OPTIONS PORTAL LOADING

- Driven tools possible (for drilling operations)

- Rotational turning possible

- NC-adjustable steady rest possible (up to two independent steady rests possible)

- Integrated measuring probe possible

- Flexible automation solution via portal possible

- Maintenance-friendly design due to integrated maintenance aisle

Technical Data Portal

Max. turning diameter

320 mm

Max. chuck diameter

400 mm

Max. peak distance

max. 1460

Max. Feed force X/Z (40 % CDF)

10 / 8 kN

Working stroke X/Z-axis

280 / 700 mm

Max. Process speed X/Z

30 / 60 m/min

Ball screw diameter X1/Z1

40 / 40 mm

Number of tools

12

Tool holder

VDI 40

Tool flight circle

730 mm

Spindle bearing diameter

90 mm

120 mm

150 mm

Spindle flange

A6

A8

A8

Drive power 100/40 % CDF

18/23 or 23/30 kW

35 / 40

52 / 67

Rated speed

1500 1/min

780 1/min

1100 1/min

Max. Speed

4500 1/min

3500 1/min

3500 1/min

Spindle flange

A6

A8

A8

Product competence

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER