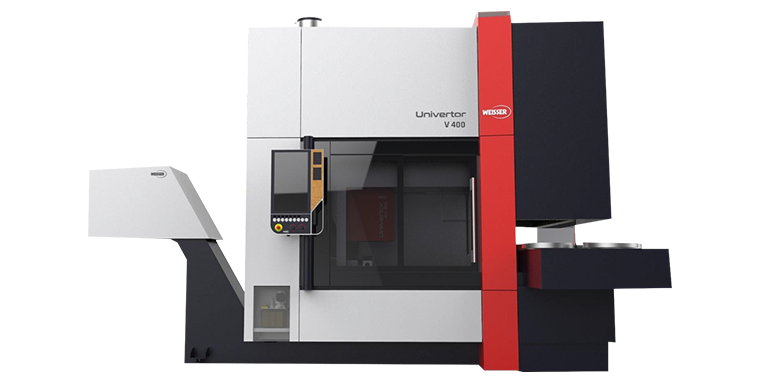

UNIVERTOR V Series

Left and right machine variants possible

Direct path measuring systems in all machining axes

Additional storage space for tools and utensils directly on the machine

NEXT GENERATION TURNING CENTER

The UNIVERTOR V offers outstanding manufacturing competence for diverse workpiece applications at highest productivity, continuous accuracy and finishing precision. In contrast to many other machine tools in the market, the UNIVERTOR V convinces with an outstanding performance and excellent precision in this machine category. Due to its high machine stability, the series is predestined for hard turning operations. Short cycle times enable high piece numbers and maximum economic efficiency. Therefore, WEISSER combines the manufacturing processes specified for the respective applications with the original WEISSER pick-up system and customized automation concepts to create a perfect, process-reliable system solution.

CONCEPTIONAL ADVANTAGES UNIVERTOR V

- Left and right machine variants possible

- Machine columns with very good stiffness behavior and optimized damping properties due to remaining sand in the model

- Linear guides designed in high accuracy and preload classes in all machine axes

- All linear guides and feed drives arranged outside the working area for protection against chips

- Direct path measuring systems in all machining axes

- High dynamics of all machine axes

- Optimum chip fall to the bottom

- Self-built turning spindles with very good concentricity and axial runout accuracy values

- Easy installation and removal of the turning spindle in the event of repairs

- Main spindle A6 or A8 according to DIN 55026 possible

- Interface in tool turret VDI or BMT

- Simplified chuck change due to large working area opening and defined chuck change aid position

- Faster throughput times due to modular system

- Large work area and long traverse paths with compact machine external dimensions

- Optimum setup friendliness and short non-productive times thanks to good accessibility, storage options and compact axis geometry in conjunction with improved axis accelerations

- Additional storage space for tools and utensils directly on the machine

OPTIONS UNIVERTOR V

- Integrated measuring probe possible

- Driven tools possible (for drilling operations)

- 4-axis machining possible (by additional turret on cross slide unit)

- Additional internal grinding unit possible

- Additional external grinding unit possible

- Combination of turning and grinding possible in smallest space

Technical data

V400

Max. turning diameter

350 mm

Max. chuck diameter

400 mm

Max. Feed force X/Z (100 % CDF)

8 / 10 kN

Working stroke X-axis

1400 / 1850 mm

Working stroke Z-axis

400 mm

Max. Process speed X/Z

75 / 30 m/min

Ball screw diameter X/Z

50 / 40 mm

Main spindle

Spindle flange

A6 (A8)

Spindle bearing diameter

120 mm

Drive power 100 % CDF

29,1 / (35,1) kW

Drive power 40 % CDF

30 / (40) kW

Rated speed

1.050 / (780) rpm

Max. Speed

4.500 / (3.500) rpm

Torque 100 % CDF

265 / (430) Nm

Torque 40 % CDF

340 / (610) Nm

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER