VERTOR C/M Series

Heavily ribbed monobloc machine base

Extremely high stiffness and thermal stability

Large working volumes with compact external dimensions of the machine

VERTOR C & VERTOR M

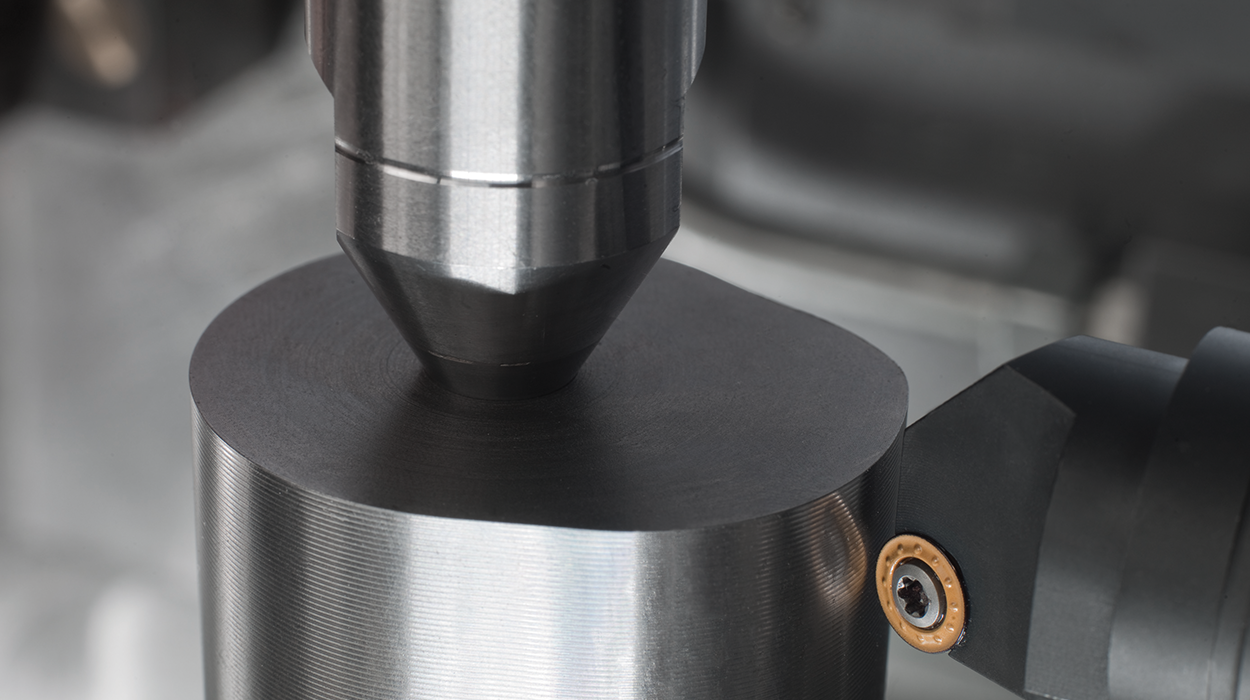

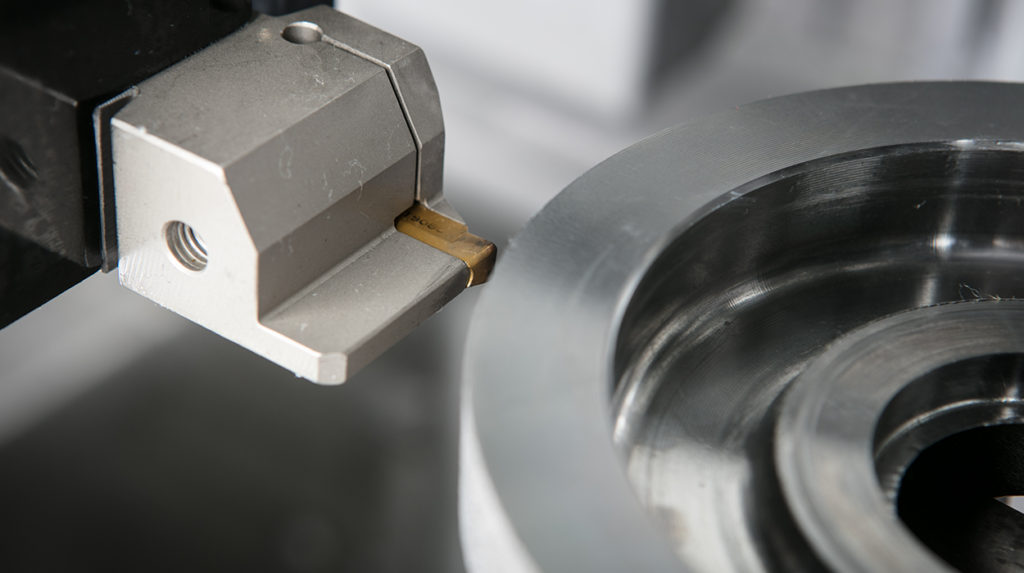

The machines of the Vertor C and M series are ideally suited for wet and dry machining of all common rotation-symmetrical workpieces with the highest precision, availability and continuous accuracy. The machines have very good accessibility with minimum space requirements and also offer the option for two or four axes. Technology integration of innovative processes such as out-of-round turning, hard turning, grinding, drilling or milling result in a significant reduction of in-house logistics processes and create high-precision machining results. The multifunctional vertical turning machines are among the world’s best machine tools in their class in terms of operating speed, availability, stability and reliability.

CONCEPTUAL ADVANTAGES VERTOR C&M

- Heavily ribbed monoblock machine column

- Extremely high rigidity and thermal stability

- Large working volumes with compact outer dimensions of the machine

- Direct drives

- Slide design for high accuracies and dynamics

- Linear path measuring systems in horizontal and vertical direction

- Maintenance-free three-phase servo drives

- Machining of chuck turned parts or shafts with tailstock and steady rest support

- 4-axis design for reduced Machining times

- Driven tools

- Optimized for manual loading

Technical data

VERTOR C

VERTOR M

Max. turning diameter

450 mm

450 mm

Max. chuck diameter

600 mm

600 mm

Max. Feed force X/Z (40 % CDF)

9 / 9 kN

9 / 9 kN

Working stroke X/Z-axis

230 / 280 (280/400) mm

230 / 280 (280/400) mm

Max. Process speed X/Z

30 / 30 m/min

30 / 30 m/min

Ball screw diameter X1/Z1

40 / 40 mm

40 / 40 mm

Number of tools

12 (2x12)

12 (2x12)

Tool holder

VDI40 / 50

VDI40 / 50

Tool flight circle

620 mm

620 mm

Main spindle

VERTOR C

VERTOR M

Spindle bearing diameter

90 mm

150 mm

Spindle flange

A6 DIN55026

A8 DIN55026

Drive power 100 % CDF

18 kW

52 kW

Drive power 40 % CDF

23 kW

67 kW

Rated speed

1.500 rpm

1.100 rpm

Max. Speed

6.000 rpm

3.500 rpm

Torque 100 % CDF

115 Nm

580 Nm

Torque 40 % CDF

146 Nm

450 Nm

Product competence

Anfrage/Request

Ich interessiere mich für eine Fertiglösung von WEISSER/I am interested in a ready-to-use solution from WEISSER